- Back to Home »

- BOILER , STEAM , SUPERHEATER , TYPES OF BOILER »

- CLASSIFICATION AND TYPES OF BOILERS

Posted by : Unknown

Tuesday, August 6, 2013

INTRODUCTION

1) KNOW THE NEED FOR STEAM ON A MOTOR VESSEL.

2) KNOW THE PRINCIPLES INVOLVED IN HEAT TRANSFER AND IN GENERATING STEAM IN A BOILER.

3) KNOW THE VARIOUS WAYS THE BOILERS CAN BE CLASSIFIED.

4) KNOW THE BASIC CONSTRUCTIONAL FEATURES OF SOME

OF THE POPULAR BOILERS USED.

OF THE POPULAR BOILERS USED.

USE OF STEAM

1) HEATING DUTIES: ME FUEL OIL HEATER, PURIFIER HEATER, OIL

TANK HEATING, CARGO HEATING, AIR CONDITIONING & HEATING PLANT, CALORIFIER,

GALLEY SUPPLY, SEA-CHESTS, TRACER LINES FOR PIPELINE HEATING ETC.

2) RUN TURBINE GENERATORS

3) RUN CARGO PUMP TURBINES IN TANKERS

4) DRIVE STEAM DRIVEN DECK MACHINERY LIKE WINCHES ETC. OPERATE

BILGE, STRIPPING AND OTHER STEAM DRIVEN PUMPS DRIVE BOILER FEED PUMP TURBINES

5) EVAPORATOR/FRESH WATER GENERATOR HEATING MEDIA

6) TANK WASHING IN TANKER SHIPS AND GENERAL CLEANING FOR BOILER SOOT BLOWING AND FOR THE STEAM ATOMISED BURNERS

7) FIRE FIGHTING AS USED IN STEAM SMOTHERING SYSTEM

8) MAIN ENGINE JACKET F.W. PREHEATER AND LUB OIL SUMP AND DRAIN TANKS

9) USE IN THE WASTE OIL, INCINERATOR, SLOP TANKS

10) USE AS A STEAM EJECTOR MEDIA FOR EJECTOR PUMPS AND VACUUM DEVICES WATER GENERATOR HEATING MEDIA

TYPES OF BOILERS

1) MAIN BOILER- PROPULSION OF THE VESSEL

2) AUXILIARY BOILER-HEATING OF HEAVY FUEL OIL USING A STEAM

HEATER, NECESSARY FOR PROPULSION WOULD QUALIFY THE SUPPLYING BOILER TO BE

REFERRED TO AS AN

AUXILIARY BOILER.

AUXILIARY BOILER.

3) TANK BOILER- A BOILER WITH LARGE WATER CARRYING CAPACITY

WHERE THE SHELL IS BEING USED AS THE PRESSURE VESSEL. MOST LOW PRESSURE

AUXILIARY BOILERS WILL COME INTO THIS CATEGORY.

4) EXHAUST GAS BOILER- BOILER OPERATED BY HOT GAS FROM ENGINE

OR OTHER EXHAUST GAS SOURCES.

5) DRUM TYPE BOILER-WATER TUBE BOILERS EMPLOYING STEAM AND

WATER DRUMS. THEY ARE ALSO KNOWN AS BENT TUBE TYPE BOILERS.

6) PACKAGE BOILER -FULLY AUTOMATIC, LOW CAPACITY BOILERS

PACKAGED INSIDE A BOX TYPE CASING, CAPABLE OF QUICK STEAM PRODUCTION AND

FLEXIBLE IN BEING POSITIONED ANYWHERE; COULD BE COIL TYPE OR FIRE TUBE TYPE.

SMOKE TUBE & WATER TUBE BOILERS

PRINCIPLE OF HEAT TRANSFER IN BOILERS

LIMITING THE STRESS

MAX WORKING PRESS. = MAX STRESS X 2 X WALL THICKNESS/DIAMETER

THEREFORE TANK TYPE BOILER MAX PRESS LIMITED TO 17.5 BAR

COMPENSATING PADS

POSITION OF MANHOLES

COMPENSATING RING

SUPPORTING FLAT SURFACE

SUNROD CHS

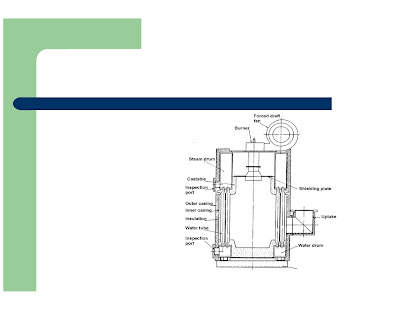

MIURA Z - BOILER

WATER TUBE BOILER

BLUE: THE DOWNCOMERS LEAD THE WATER FROM THE STEAM DRUM TO

THE WATER DRUM AND THE WATERWALLS

HEADERS.

HEADERS.

RED AND BLUE: THE EVAPORATION TUBES AND THE WATER WALLS LEAD

THE WATER AND STEAM EMULSION BACK TO

THE STEAM DRUM.

THE STEAM DRUM.

RED: THE STEAM PASSES THROUGH THE SUPERHEATER BEFORE IT

LEAVES THE BOILER FOR THE CONSUMERS.

KEEP SUPERHEATER VENT OPEN AND MAINTAIN FLOW TO PREVENT

OVERHEATING.